Affordable and Sustainable Commercial Building Materials

Commercial construction budgets face mounting pressure from material price volatility and rising labor costs, making cost-effective building material options essential for maintaining profitability. Value engineering applies a structured evaluation of functions to cut unnecessary expenses while preserving performance, and sustainable selections translate into long-term savings on energy and maintenance. This guide empowers businesses to:

- Master value engineering processes for cost reduction and quality gains

- Compare top economical materials and their lifecycle advantages

- Leverage advanced cost–saving construction techniques

- Identify reliable suppliers meeting budget-conscious and green criteria

- Explore case studies demonstrating real savings

- Harness digital marketing strategies to generate local leads for material suppliers

By blending technical insight with practical examples, companies can optimize material choices and cultivate growth through targeted digital outreach.

What Is Value Engineering and How Does It Reduce Commercial Construction Costs?

Value engineering is a systematic method that analyzes project functions, identifies lower-cost alternatives, and improves overall value by balancing performance with expense. It eliminates redundant features while ensuring structural integrity, and projects often realize savings up to 20 percent of total costs. For instance, substituting conventional finishes with high-performance composites can maintain appearance and durability at a fraction of the budget, laying the groundwork for an effective material selection strategy.

Value Engineering and Cost Reduction in Construction

Value engineering is a systematic approach that can lead to significant cost savings in construction projects by analyzing project functions and identifying lower-cost alternatives while maintaining performance. Studies have shown that value engineering can reduce project costs by up to 20%.

Dell’Isola, A. J., Value Engineering in the Construction Industry (1997)

What Are the Key Stages of the Value Engineering Process?

Value engineering follows a clear sequence of activities to uncover cost-saving opportunities:

- Information Gathering – Define project requirements, budgets, and functional goals through stakeholder interviews.

- Function Analysis – Break down each component’s essential role and cost drivers.

- Creative Phase – Brainstorm alternative materials, systems, or methods that deliver required functions.

- Evaluation – Compare proposed solutions against criteria such as cost, performance, and sustainability.

- Development – Refine selected alternatives into detailed design proposals.

- Presentation – Present findings and recommendations to decision-makers with cost-benefit analyses.

- Implementation – Integrate approved changes into project documents and procurement processes.

Completing these stages ensures that budget constraints align with quality expectations, which naturally leads into evaluating the impact on ROI.

How Does Value Engineering Improve Project Quality and ROI?

Value engineering enhances project outcomes by:

- Optimizing Resource Allocation – Redirecting funds toward high-impact areas strengthens critical systems without inflating costs.

- Streamlining Schedules – Early identification of simplified methods reduces delays and labor expenses.

- Elevating Functionality – Innovative substitutes often deliver equal or superior performance at reduced cost, increasing asset value.

By strategically balancing cost and performance, projects achieve higher return on investment and improved longevity.

Who Are the Main Stakeholders Involved in Value Engineering?

Successful value engineering requires collaboration among:

- Owners/Developers – Define business objectives, budget limits, and long-term goals.

- Architects and Engineers – Lead functional analysis and technical feasibility assessments.

- General Contractors – Provide cost data, construction insights, and logistical considerations.

- Certified Value Specialists (CVS) – Facilitate structured VE workshops and guide alternative development.

- Facility Managers – Advise on operational needs, maintenance implications, and lifecycle performance.

Engaging all parties ensures that cost-saving measures align with design intent and operational realities, paving the way for selecting specific materials.

Which Building Materials Are Most Cost-Effective for Commercial Construction?

Cost-effective building materials blend low initial expense with durability, energy efficiency, and minimal maintenance requirements. By evaluating embodied energy, procurement costs, and lifecycle performance, project teams can achieve balanced value without sacrificing long-term sustainability. For example, combining recycled steel with insulated concrete forms reduces both material spend and ongoing thermal losses.

| Material | Cost Saving Mechanism | Key Benefit |

|---|---|---|

| Recycled Steel | Uses post-consumer scrap | Lowers raw material expense and waste |

| Mass Timber | Prefabricated fabrication | Speeds assembly and reduces labor overhead |

| Insulated Concrete Forms (ICF) | Integrated insulation and structure | Cuts energy bills and construction time |

| Bamboo | Rapid renewability and local harvest | Lowers procurement cost and carbon footprint |

| Prefabricated Panels | Off-site manufacturing | Minimizes on-site labor and weather delays |

| Fly Ash Bricks & AAC | Utilizes industrial byproducts | Offers insulation, fire resistance, weight reduction |

This comparison highlights core mechanisms behind each material’s affordability and sets the stage for exploring individual advantages.

What Are the Benefits of Using Recycled Steel in Commercial Buildings?

Recycled steel delivers high structural strength while reducing raw-material costs by up to 40 percent.

- It lowers embodied carbon by repurposing scrap, supporting sustainability goals.

- Fabricated sections arrive ready to install, shortening delivery times and labor expenses.

- Its uniform quality and predictable performance improve project reliability.

Benefits of Recycled Steel in Construction

Using recycled steel in construction offers several advantages, including a reduction in raw material costs and a decrease in the environmental impact due to the reuse of scrap materials. Recycled steel can lower raw material expenses by up to 40%.

Chini, A. R., & Teshigawara, T., Recycled Steel in Construction (2002)

Recycled steel’s balance of affordability, durability, and environmental stewardship makes it a primary choice before examining mass timber advantages.

How Does Mass Timber Offer Economical and Sustainable Advantages?

Mass timber systems leverage engineered wood panels and beams to provide load-bearing capacity at lower weight and cost than steel or concrete.

- Prefabrication ensures tight tolerances and rapid on-site assembly, reducing labor.

- Wood’s negative carbon footprint sequesters carbon, advancing green building targets.

- Superior strength-to-weight ratio allows lighter foundations and simplified structural designs.

Mass timber’s blend of speed, sustainability, and cost savings leads naturally into insulated concrete form benefits.

Why Choose Insulated Concrete Forms (ICF) for Energy Efficiency and Cost Savings?

ICF integrates structural walls with continuous insulation, delivering:

- 50 percent lower heating and cooling bills through reduced thermal bridging.

- Rapid block stacking and pour cycles that streamline construction schedules.

- Enhanced fire resistance and soundproofing, reducing secondary costs.

ICF’s dual role as structure and envelope exemplifies how innovative materials cut both construction and lifecycle expenses, segueing to bamboo’s offerings.

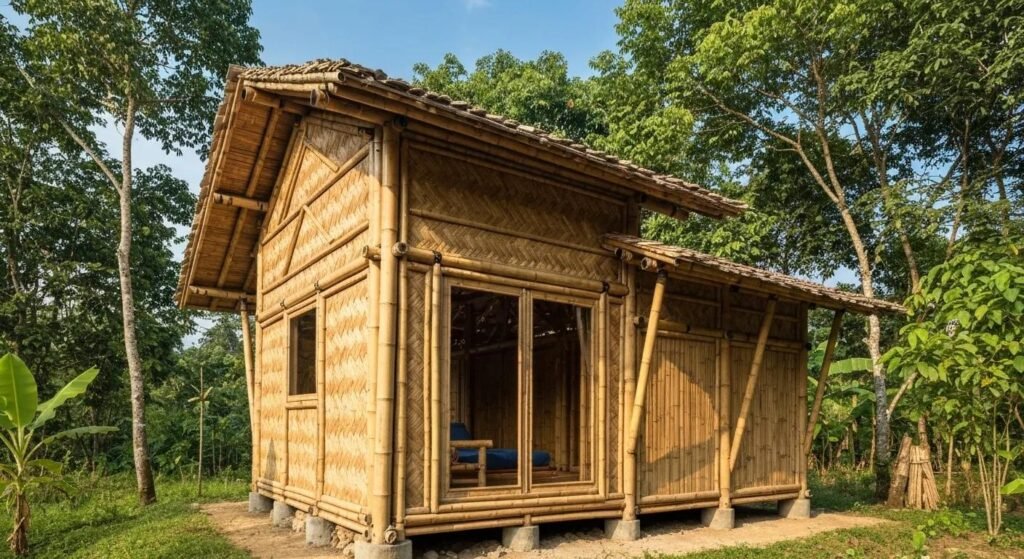

What Makes Bamboo a Sustainable and Affordable Commercial Building Material?

Bamboo’s rapid growth cycle and local availability translate into competitive pricing and eco-credentials.

- Matures in 3–5 years, ensuring steady supply without deforestation.

- Exhibits tensile strength rivaling steel, suitable for framing and decorative elements.

- Its lightweight nature reduces transportation costs and foundation requirements.

Bamboo’s renewability and structural capacity encourage a shift toward prefabricated component strategies.

How Do Prefabricated and Modular Components Speed Up Construction and Reduce Costs?

Off-site manufacturing of panels or modules ensures consistent quality and significantly lowers site labor:

- Weather-independent fabrication accelerates project timelines.

- Standardized modules cut material waste by up to 90 percent.

- Quality controls in factory settings reduce rework and on-site inspection costs.

Prefabrication’s process synergy paves the way for fly ash brick and AAC advantages.

What Are the Advantages of Fly Ash Bricks and Autoclaved Aerated Concrete (AAC)?

Fly ash bricks and AAC units harness industrial byproducts for lightweight, insulating masonry:

- Fly ash bricks reuse waste from power plants, lowering material expense.

- AAC panels provide R-values double that of traditional concrete, cutting energy bills.

- Reduced weight simplifies foundations and lowers handling costs.

Innovative use of byproducts underscores how material selection drives comprehensive cost control before lifecycle analysis.

How Can Lifecycle Cost Analysis Maximize Long-Term Savings on Commercial Building Materials?

Lifecycle cost analysis evaluates initial purchase, installation, operation, maintenance, and disposal expenses to identify the true lowest-cost solution over a building’s service life. This method ensures that a cheaper upfront material doesn’t incur higher energy or repair bills later, guiding decisions toward holistic value.

Why Is Considering Operational and Maintenance Costs Essential?

Operational energy consumption often exceeds construction costs over decades, and maintenance can represent a large recurring expense:

- High-performance envelopes reduce HVAC sizing and run-time.

- Durable surfaces minimize repair frequency and downtime.

- Predictable maintenance schedules help budget accurately for lifecycle expenditures.

Linking maintenance forecasts with material choices ensures sustainable savings and sets up analysis of environmental impacts.

How Do Sustainable Materials Impact Lifecycle Costs and Environmental Footprint?

Sustainable materials deliver dual benefits of reduced energy consumption and lower carbon emissions over time:

- Renewable resources like mass timber store carbon, offsetting embodied emissions.

- High-insulation solutions such as ICF and AAC reduce annual energy outlay.

- Recycling-capable components minimize end-of-life waste fees and liability.

Quantifying environmental and cost impacts together supports more informed procurement, leading to tool selection for analysis.

What Tools and Methods Are Used for Lifecycle Cost Analysis in Construction?

Practitioners employ specialized software and industry standards to model expenses:

- Whole Life Cost (WLC) Software – Simulates cost streams over defined time horizons.

- LEED and BREEAM LCC Modules – Integrate certification points with cost forecasting.

- Spreadsheet-Based Parametric Models – Offer quick sensitivity analyses for design alternatives.

Selecting the right tool aligns financial projections with sustainability targets and transitions into construction technique synergies.

What Construction Techniques Complement Cost-Effective Material Use to Optimize Budgets?

Pairing effective materials with efficient delivery methods amplifies savings by reducing waste, streamlining coordination, and compressing schedules.

How Does Lean Construction Minimize Waste and Reduce Expenses?

Lean construction applies continuous improvement and just-in-time workflows to:

- Eliminate non-value tasks, cutting inventory costs.

- Synchronize subcontractor schedules, preventing idle labor.

- Use value stream mapping to refine material deliveries and avoid on-site stockpiles.

Waste reduction through lean principles directly enhances material cost benefits, opening the door to delivery models like design-build.

What Are the Benefits of Design-Build Delivery for Cost Control?

Design-build integrates architectural and construction teams under one contract, yielding:

- Early cost certainty through joint estimation and value engineering.

- Fewer change orders as budgets and design evolve in lockstep.

- Accelerated timelines by overlapping design and construction phases.

This unified delivery model supports smarter pre-construction planning, which further drives budget optimization.

How Does Smart Pre-Construction Planning Enhance Material Cost Savings?

Front-end planning that aligns scope, schedule, and supply chain reduces risks and hidden fees:

- Detailed procurement calendars prevent price escalations from late orders.

- Constructability reviews identify more economical build methods before mobilization.

- Early contractor involvement secures bulk purchasing discounts and long-lead item commitments.

Coordinated planning cements the synergy between method and material efficiency, leading naturally to supplier selection.

Where Can Businesses Find Reliable Suppliers of Affordable and Sustainable Commercial Building Materials?

Securing trusted vendors ensures material specifications, delivery reliability, and competitive pricing, supporting both budget and performance requirements.

What Are the Top Commercial Building Material Suppliers for Budget-Conscious Projects?

Leading suppliers combine broad inventories with value-driven pricing models:

- National distributors offering bulk discounts on recycled steel and concrete products.

- Regional mass timber fabricators specializing in engineered panels.

- Modular component manufacturers providing turn-key systems with predictable costs.

- RJT Construction LLC’s commercial general contractor services prioritize competitive pricing, high-quality workmanship, and timely delivery for value-focused developments.

Partnering with suppliers who understand cost-effective material strategies ensures on-budget project delivery and seamless procurement.

How Does Local Sourcing Reduce Costs and Environmental Impact?

Buying from nearby producers offers dual advantages of lower transport expenses and reduced carbon footprint:

- Shorter delivery routes slash freight fees and expedite schedules.

- Closer relationships facilitate bulk rate negotiations and just-in-time orders.

- Support for local economies often yields preferential service terms and warranty responsiveness.

Local sourcing strategies reinforce sustainable procurement decisions and prepare for evaluating supplier credentials.

What Certifications Should Suppliers Have for Sustainable Materials?

Certifications signal verified eco-performance and quality controls:

- Forest Stewardship Council (FSC) for responsibly sourced timber.

- UL Environment listings for recycled content in concrete and metals.

- ENERGY STAR® or ISO 14001 environmental management standards for manufacturing facilities.

Working with credentialed suppliers reduces risk and aligns projects with green building goals, enabling compelling proof points in real projects.

What Are Real-World Examples of Successful Commercial Projects Using Cost-Effective Materials?

Examining completed developments reveals how theory translates into measurable savings and performance enhancements.

How Have Recycled Steel and Mass Timber Delivered Financial and Environmental Benefits?

A mid-rise office building replaced primary steel framing with 40 percent recycled content and mass timber floor panels, achieving:

- 18 percent reduction in structural expenditure compared to new steel.

- 25 percent lower embodied carbon, supporting sustainability certification.

- 30 percent faster erection schedule, cutting site overhead costs.

These outcomes underscore how combining materials can amplify value and resource efficiency.

What Savings and Efficiencies Resulted from Prefabricated Construction Methods?

A modular hotel project utilized factory-built room pods and prefabricated façade panels to realize:

- 35 percent reduction in on-site labor costs.

- 20 percent shorter project duration, minimizing financing expenses.

- Consistent quality control, reducing rework by half.

Prefabrication’s integrated process yielded quantifiable budget relief and schedule acceleration.

How Do LEED-Certified Projects Demonstrate ROI with Sustainable Materials?

LEED Platinum commercial facilities employing ICF, AAC, and recycled components reported:

- 40 percent lower annual energy costs.

- Rental premium increases of up to 31 percent over conventional buildings.

- Enhanced tenant retention driven by wellness and efficiency features.

Certification-driven ROI exemplifies the financial upside of eco-conscious material decisions.

How Can Digital Marketing Help Commercial Construction Businesses Promote Cost-Effective Building Materials?

A targeted online strategy educates prospects, amplifies brand authority, and drives qualified local leads for material suppliers and contractors.

What Strategies Drive Local Leads for Commercial Building Material Suppliers?

Effective local lead generation tactics include:

- Geotargeted SEO for queries like “affordable commercial ICF suppliers near me.”

- Google Business Profile optimization with project gallery visuals and client reviews.

- Localized content hubs featuring case studies and material comparisons tailored to regional regulations.

These approaches ensure high-intent buyers connect with suppliers when budgets and schedules are critical.

How Does Content Marketing Educate and Convert Construction Industry Clients?

Educational blogs, whitepapers, and interactive tools build trust and guide procurement decisions:

- In-depth guides on lifecycle cost comparisons engage developers and facility managers.

- Webinars with value engineering experts foster professional credibility.

- ROI calculators clarify savings from materials like mass timber or recycled steel.

By demonstrating expertise, suppliers convert research-stage prospects into purchase orders.

Why Is Data-Backed Digital Marketing Essential for Construction Material Businesses?

Analytics-driven campaigns maximize ROI and refine lead pipelines:

- Conversion tracking links marketing spend to RFQs and material orders.

- A/B testing of landing pages pinpoints messaging that motivates procurement teams.

- Attribution models reveal the highest-value content assets for ongoing investment.

Data empowers continuous optimization, ensuring sustained growth in a competitive marketplace.

Strategically integrating digital marketing amplifies material suppliers’ visibility and positions them as trusted partners in delivering cost-effective, sustainable solutions.

Commercial construction businesses that combine value engineering with smart material choices and leverage targeted digital outreach stand to gain both immediate and enduring competitive advantage. Contact us for a digital marketing consultation to grow your construction business.