Insulation is a critical component in metal building projects, significantly impacting their performance and efficiency. Metal buildings are particularly susceptible to temperature fluctuations, which can lead to high energy costs and uncomfortable indoor environments. Proper insulation addresses these issues by regulating interior temperatures, improving energy efficiency, and providing cost savings.

Additionally, it prevents condensation buildup, which can cause structural damage and mold growth. Insulating metal buildings also enhances sound absorption, creating a quieter and more pleasant interior space. In this guide, we will explore the best insulation options for metal building projects in 2024, focusing on their benefits, installation processes, and how they contribute to energy efficiency and cost savings.

Understanding Metal Building Insulation

The Importance of Insulating Metal Buildings

Insulating metal buildings is essential for several reasons:

- First, insulation helps regulate the interior temperature, keeping the building warm in the winter and cool in the summer. This regulation reduces the workload on heating and cooling systems, leading to lower energy consumption and costs.

- Second, proper insulation prevents condensation by reducing the temperature difference between the metal framing and the interior air. This is crucial in avoiding moisture buildup, which can lead to corrosion, mold, and structural damage.

- Lastly, insulation can improve indoor air quality and comfort by maintaining a stable temperature and reducing drafts.

Types of Insulation for Metal Buildings

There are several insulation options available for metal buildings, each with its unique advantages and applications. The most popular types include:

- Fiberglass Insulation: Known for its affordability and ease of installation, fiberglass insulation provides good thermal performance and is available in various forms, such as blankets, rolls, and loose-fill.

- Spray Foam Insulation: Offers a high R-value and excellent air sealing properties, making it ideal for preventing air leakage and maintaining energy efficiency.

- Insulated Metal Panels (IMPs): Pre-fabricated panels with insulation sandwiched between two metal skins, offering superior thermal performance and a streamlined installation process.

Selecting the right insulation depends on factors such as budget, climate, and the specific needs of the building. Each type of insulation has its pros and cons, making it important to consider these factors carefully to ensure optimal performance and cost-effectiveness.

Fiberglass Insulation for Metal Buildings

Fiberglass Insulation: An Affordable Solution

Fiberglass insulation is a popular choice for metal building projects due to its affordability and effectiveness. It is widely used for its good thermal performance and ease of installation.

One of the primary advantages of fiberglass insulation is its cost-effectiveness, making it accessible for various budgets. It also offers flexibility in application, available in different forms such as blankets, rolls, and loose-fill. However, fiberglass insulation has its drawbacks. It can be susceptible to moisture accumulation, which may reduce its insulating properties over time.

Additionally, improper installation can lead to gaps, reducing its effectiveness. Despite these cons, fiberglass remains a go-to solution for many metal building insulation projects because of its balance of cost and performance.

Types of Fiberglass Insulation:

- Blankets: Pre-cut lengths that fit standard spacing in wall and roof framing.

- Rolls: Continuous lengths that can be cut to size, ideal for larger areas.

- Loose-fill: Small particles blown into spaces, perfect for filling irregularly shaped areas and cavities.

Installation Process for Fiberglass Insulation

Installing fiberglass insulation in metal buildings involves several key steps to ensure optimal performance.

- First, measure and cut the fiberglass blankets or rolls to fit the wall cavities and roof panels.

- Next, secure the insulation using appropriate fasteners or adhesives, ensuring it fits snugly without compressing.

- Finally, seal any gaps with additional insulation or sealant to prevent air leakage and ensure a continuous thermal barrier.

Proper installation is crucial to maximize the benefits of fiberglass insulation, such as improved energy efficiency and temperature regulation.

Spray Foam Insulation for Metal Buildings

Spray Foam Insulation: A Comprehensive Seal

Spray foam insulation is highly regarded for its superior sealing capabilities and high R-value, making it an excellent choice for metal building projects. It is particularly effective at preventing air leakage, significantly enhancing energy efficiency by maintaining a consistent interior temperature.

Spray foam insulation expands upon application, filling gaps and voids that other insulation types might miss. This characteristic makes it ideal for complex building structures and hard-to-reach areas. There are two main types of spray foam insulation: open-cell and closed-cell.

Open-cell spray foam is less dense and provides good thermal resistance with sound absorption properties, while closed-cell spray foam is denser, offering higher R-values and better moisture resistance.

Both types of spray foam insulation contribute to reducing energy consumption and improving overall building performance, making them a comprehensive solution for metal building insulation needs.

How to Install Spray Foam Insulation?

Installing spray foam insulation in metal buildings involves a meticulous process to ensure maximum effectiveness. First, prepare the surface by cleaning and ensuring it is free from dust, dirt, and moisture. Then, apply the spray foam using specialized equipment, starting from the bottom and working your way up to ensure even coverage.

The foam will expand and fill gaps, creating a comprehensive seal. It’s important to apply the foam in layers to achieve the desired thickness and R-value. Proper ventilation and protective gear are crucial during installation to ensure safety and effective application. Allow the foam to cure fully before finishing the interior.

Insulated Metal Panels (IMPs)

Insulated Metal Panels: A Complete Solution

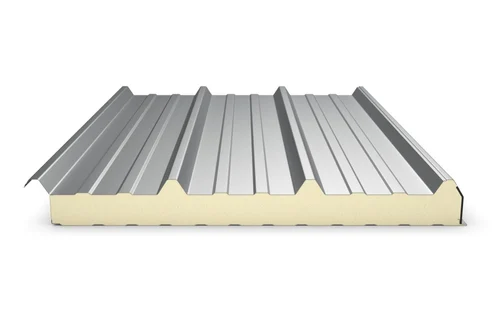

Insulated Metal Panels (IMPs) are an excellent choice for metal building projects, offering a comprehensive insulation solution that combines superior thermal performance with ease of installation. These panels consist of an insulating foam core sandwiched between two metal skins, providing exceptional thermal resistance and reducing heat transfer.

IMPs are available in a variety of finishes and colors, allowing for aesthetic flexibility in design. Their design simplifies the installation process, often reducing labor costs and time. IMPs are ideal for applications where high energy efficiency, structural strength, and quick installation are priorities, making them a popular choice for commercial, industrial, and residential metal building projects.

Installing Insulated Metal Panels

Installing Insulated Metal Panels involves several key steps to ensure a secure and effective installation. Begin by preparing the building framework, ensuring it is straight and level. Next, position the panels and secure them to the metal framing using fasteners or clips, ensuring they are tightly aligned to prevent gaps.

Seal the joints between panels with appropriate sealant or gaskets to enhance thermal performance and prevent air leakage. Follow manufacturer guidelines for fastening and sealing to achieve the best results. Proper installation of IMPs not only enhances energy efficiency but also contributes to the structural integrity of the metal building.

Advanced Insulation Options

Rigid Board Insulation for Metal Buildings

Rigid board insulation is a high-performance solution for insulating metal buildings. These boards, typically made from materials like polystyrene, polyisocyanurate, or polyurethane, offer exceptional thermal resistance with high R-values. One of the primary advantages of rigid board insulation is its durability and moisture resistance, making it suitable for environments prone to humidity and temperature fluctuations.

The boards are easy to cut and install, fitting snugly between metal framing or directly onto surfaces. Rigid board insulation is particularly effective for insulating walls, roofs, and floors, providing a continuous thermal barrier that minimizes heat loss and enhances energy efficiency.

Its structural strength also adds an extra layer of protection to the building envelope, making it an excellent choice for various metal building applications, including commercial, industrial, and residential projects.

Reflective Foil Insulation: Enhancing Thermal Performance

Reflective foil insulation is designed to enhance the thermal performance of metal buildings by reflecting radiant heat away from the interior spaces. This type of insulation consists of a reflective aluminum foil layer combined with other materials like bubble wrap or foam.

One of the key benefits of reflective foil insulation is its ability to significantly reduce heat transfer, making it highly effective in hot climates where radiant heat is a major concern. It is lightweight, easy to install, and can be used in conjunction with other insulation types to boost overall energy efficiency.

Reflective foil insulation is ideal for use in roofs, walls, and attic spaces, particularly in metal building projects where controlling heat gain is crucial. Its reflective properties help maintain cooler indoor temperatures, reduce the load on HVAC systems, and ultimately lower energy costs.

Insulation Installation and Maintenance

Preparing Your Metal Building for Insulation

Preparing your metal building for insulation is crucial to ensure the effectiveness and longevity of the insulation system. Start by inspecting the building for any existing leaks, gaps, or structural issues. Seal all leaks and repair any damage to prevent moisture infiltration, which can compromise the insulation’s performance.

Ensure the building is weatherproof by applying a vapor barrier to areas prone to moisture buildup. This barrier helps to protect the insulation material from condensation. Additionally, clean all surfaces where insulation will be applied to remove dirt, dust, and debris.

This preparation not only ensures a seamless installation process but also enhances the insulation’s ability to regulate temperature, improve energy efficiency, and prevent condensation.

Professional vs. DIY Insulation Installation

When deciding between professional insulation installation and a DIY approach, several factors should be considered. Professional installation offers expertise and efficiency, ensuring the insulation is installed correctly to maximize its benefits. Professionals have the right tools and knowledge to handle complex installations, avoid common pitfalls, and ensure compliance with local building codes.

However, this option can be more costly than DIY. On the other hand, DIY insulation installation can save money and provide a sense of accomplishment. It is essential to research and follow best practices meticulously to avoid mistakes that could compromise the insulation’s effectiveness.

Consider the complexity of the project, available time, and personal skill level when making this decision. For larger or more intricate metal building projects, professional installation is often recommended to ensure optimal performance.

Maximizing Energy Efficiency and Cost Savings

Proper insulation is key to reducing energy consumption and costs in metal buildings. High-quality insulation minimizes heat transfer, keeping the building cooler in summer and warmer in winter, thus reducing the need for heating and cooling. This translates to lower energy bills and significant cost savings over time.

To calculate the payback period and return on investment (ROI) for insulation projects, consider the initial cost of insulation and installation, the reduction in energy bills, and the expected lifespan of the insulation.

For example, if an insulation project costs $5,000 and saves $500 annually in energy costs, the payback period would be 10 years. After this period, the continued savings contribute to the ROI. Improved energy efficiency also increases the building’s value and comfort, making insulation a wise long-term investment.

Choosing the Best Insulation for Your Metal Building

Selecting the best insulation for your metal building project in 2024 involves considering several key factors.

First, assess the climate in your area; for colder regions, insulation with higher R-values is essential, while in hotter climates, reflective insulation can significantly reduce cooling costs. The building’s use is also crucial; storage facilities may have different insulation requirements compared to workshops or living spaces.

Budget is another important factor—while high-quality insulation might have a higher upfront cost, it often results in greater energy savings and a shorter payback period..

Lastly, evaluate the energy efficiency of the insulation options, focusing on both R-value and U-factor to ensure optimal performance

For the best results, choose insulation that aligns with your specific needs and local building codes. Consider consulting with a professional to ensure proper installation and to maximize the insulation’s benefits. Whether you opt for fiberglass, spray foam, insulated metal panels, rigid board, or reflective foil insulation, making an informed decision will enhance the comfort, efficiency, and longevity of your metal building.